EFFECTS ON THE SUSPENSION

“Temperature affects the oil, the gas pressure, and the seals in the shock. It can also increase and/or decrease certain tolerance fits inside the damper itself. Aluminum shocks may be affected differently than steel, as well as aluminum pistons compared to steel pistons. During the course of your race, the damper changes. Do you know what is happening to it from the beginning to the end? Is it important?”

EFFECTS ON THE SUSPENSION

ROEHRIG ENGINEERING TEST REPORT

“Temperature affects the oil, the gas pressure, and the seals in the shock. It can also increase and/or decrease certain tolerance fits inside the damper itself. Aluminum shocks may be affected differently than steel, as well as aluminum pistons compared to steel pistons. During the course of your race, the damper changes. Do you know what is happening to it from the beginning to the end? Is it important?”

SPECIFICATIONS

Handle

Dimension: 109x83x64 mm

Weight: 90g

Material: Fibreglass,

Reinforced plastic,

Thermoplastic polyurethane

Power Supply

Dimension: 235x77x50 mm

Weight: 700 g

Material: Aluminium + Rubber

Power: 100-240 Volt

Cords

Dimension: Ø6, 1500 mm

Weight: 80g

Material: Silicone

ATTENTION: Read the user guide before purchase!

TRACK TEST #01 – RR50W

TEST RIDER: Lukas Backström

#01 TESTS CONDUCTED

Fork heater test 07/07/16

Air temperature -16 degrees

Track Surface Temperature – 21 degrees

Track – Karlskoga motorstation

Bike – 2015 Yamaha R1M

Fork heater tested -50w

Time fork was heated for -15 minutes

External temperature of fork leg above forsk seal -33 degree

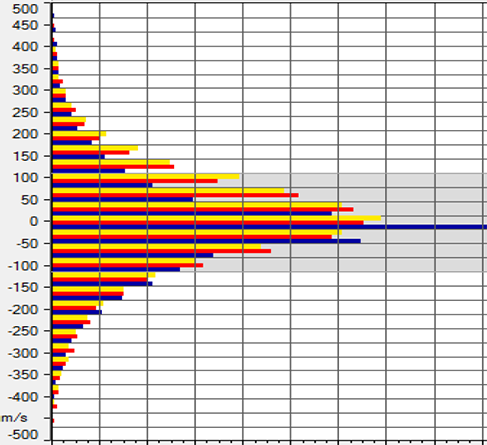

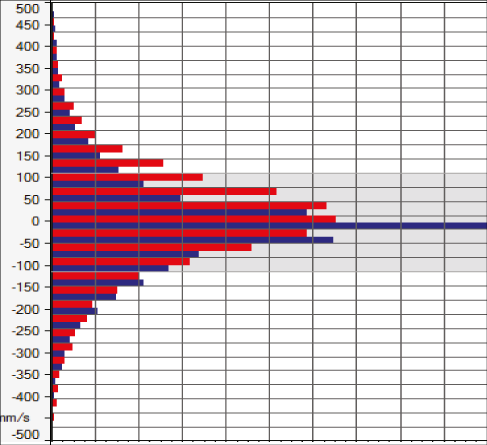

Blue – First rolling lap without fork heater (laptime 1.07.884)

Red – First rolling lap after fork had been heated with RR50W heater (laptime 1.07.250)

Figure 1 shows the amount of time the suspension spends traveling at certain speeds over 1 lap. This clearly shows that after the fork was heated the bike was much more free to move while compressing the suspension, while very little difference occurred to the suspension rebound. You can see that the bike spends a lot more time traveling in the 50mm/s – 200mm/s range.

#02 RESULTS - FIGURE 1

Figure 1 - Front fork travel derivative over time.

#03 RESULTS - FIGURE 2

Fork heater test 07/07/16

In figure 2 we introduce data from lap 9 of a test where the heater wasn’t used. You can clearly see how close the heated test is compared to the bike after it has had time to naturally heat the fork oil.

#04 RESULTS - FIGURE 2

Figure 2 - Front fork travel derivative over time.